- Fault codes for RAC and semi-FS inverter units

- General questions

- Wish Lists, shopping baskets & offers

- Create offer for end customer

- Manage users

- To search & find

- Information & purchasing

- error codes

- Fault codes for RAC and semi-FS inverter units

- Fault code ECOi ME1 & MF1

- Fault codes FS devices

- Fault code ECOi ME2 & MF2

- Meine Auswertungen

- Explanatory videos

- Features mySchiessl

- Störungscodes Single-/Multi-Split

- Störungscodes PACi NX

Fault codes for RAC and semi-FS inverter units

With the infrared remote control:

In the event of a fault, the unit is automatically switched off and the timer LED flashes. The error is stored in memory. The type of fault can be determined using the self-diagnosis function and the fault codes:

- Press the self-diagnosis button (CHECK) on the remote control for more than 5 seconds to switch on the self-diagnosis mode. The remote control then displays "- -". (No signal has yet been transmitted to the indoor unit, ie there is no beep and the POWER LED does not light up.)

- Press the TIMER

or

or  button, the code "H00" appears (no malfunction) and a signal is sent to the indoor unit.

button, the code "H00" appears (no malfunction) and a signal is sent to the indoor unit. - Press the TIMER

again

again  . Each time the button is pressed, a new fault code is displayed and sent to the indoor unit.

. Each time the button is pressed, a new fault code is displayed and sent to the indoor unit. - If the fault code sent matches the actual fault in the unit, the POWER LED lights up for 30 seconds and it sounds

a 4 second beep. If the fault code does not match, the POWER LED lights up for 0.5 seconds and there is no beep. - If no button is pressed on the remote control for 30 seconds, or if you press the CHECK button again for 5 seconds, the self-diagnosis mode is switched off again. The LED goes out when the device is switched off or the AUTObutton on the unit is pressed.

With the cable remote control (CZ-RD52CP):

In the event of a fault, the device is automatically switched off and the mode LED is OFF. The OFF indicator also does not appear on the remote control. The error code can be read using the remote control as follows:

- Press the self-diagnosis button (CHECK) on the remote control for more than 5 seconds to switch on the self-diagnosis mode. The remote control then displays "- -".

- Press the TIMER

or

or  key, the code "H00" appears (no fault).

key, the code "H00" appears (no fault). - Press the TIMER

or

or  key again. Each time the button is pressed, a new fault code is displayed and sent to the indoor unit.

key again. Each time the button is pressed, a new fault code is displayed and sent to the indoor unit. - If the fault code sent matches the actual fault in the unit, the POWER LED stays lit up.

- If no button is pressed on the remote control for 30 seconds, or if you press the CHECKbutton again for 5 seconds, the self-diagnosis mode is switched off again.

F11 Fault when switching between cooling and heating cycle

Preconditions: 4 times in 20 minutes

Check priority:

- Switchover valve

- Valve coil

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty outdoor unit circuit board.

- Faulty switchover valve.

To check and remedy see picture.

F17 Not running indoor unit frost protection

Preconditions: Only for multi-split inverter systems

Priority check:

- Expansion valve is leaking

- Pipe temperature sensor of the indoor unit

Possible causes:

- Faulty expansion valve.

- Faulty line temperature sensor.

- Faulty outdoor unit circuit board.

To check and remedy see figure.

F90 Power factor control

Preconditions: 4 times in 20 minutes

Check priority: Power factor control voltage

- DC voltage spike due to voltage supply fluctuation.

- DC voltage spike due to compressor malfunction or unequal winding resistance.

- Faulty outdoor unit fan.

- Faulty compressor.

- Faulty PFC circuit of the outdoor unit circuit board.

- Faulty choke coil.

For checking and rectification see picture.

F91 Cooling circuit fault

Preconditions: 2 times in 20 minutes

Check priority: No refrigerant (-way valve closed)

- Lack of refrigerant (leakage).

- Low compression of the compressor.

- Service valve closed.

- Incorrect measured value of the line temperature sensor or the intake temperature sensor in the indoor unit.

- Outdoor unit board.

To check and rectify see picture.

F93 Incorrect compressor rpm

Preconditions: 4 times in 20 minutes

Check priority:

- Lack of refrigerant (leakage).

- Low compression of the compressor.

- Service valve closed.

- Incorrect measured value of the line temperature sensor or the intake temperature sensor in the indoor unit.

- Outdoor unit board.

To check and rectify see picture.

F94: High pressure pressostat in the outdoor unit has triggered

Preconditions: 4 times in 20 minutes

Check priority:

- Switch valve

- Valve coil

- High pressure pressostat

- Condenser fan

Possible causes:

- Short circuit of the warm blown air.

- Outdoor unit fan motor defective.

- Line temperature sensor in the outdoor unit defective.

- Outdoor unit board defective.

F95 High pressure protection in cooling mode

Preconditions: 4 times in 20 minutes

Check priority:

- Short circuit of the warm blown air.

- Outdoor unit fan motor defective.

- Line temperature sensor in the outdoor unit defective.

- Outdoor unit board defective.

To check and remedy see picture.

F96 Compressor overheat protection

Preconditions: 4 times in 20 minutes

Check priority:

- Refrigerant shortage

- Compressor

Possible causes:

- Refrigerant shortage (leakage).

- Incorrect measured value of the compressor or hot gas temperature sensor.

- Pipe kinked or service valve (s) half closed.

F96 Power transistor module overheat protection

Priority check:

- Insufficient heat dissipation from the outdoor unit.

- Excess refrigerant.

- Power transistor defective.

- Service valve closed.

To check and remedy see picture.

F98 Protection against excessive total operating current

Preconditions: 3 times in 20 minutes

Check priority:

- Refrigerant excess

- Insufficient heat emission

Possible causes:

- Overcurrent due to compressor malfunction.

- Overcurrent due to defective outdoor unit circuit board.

- Overcurrent due to defective inverter

- Condenser circuit.

- Overcurrent due to excessive refrigerant charge

For checking and rectification see picture.

F99 Direct current spikes in outdoor unit

Preconditions: 7 times in a row

Priority check:

- Outdoor unit circuit board

- Power transistor (IPM)

- Compressor

Possible causes:

- Compressor fault

- Defective power transistor module

- Defective outdoor unit board

To check and rectify see figure.

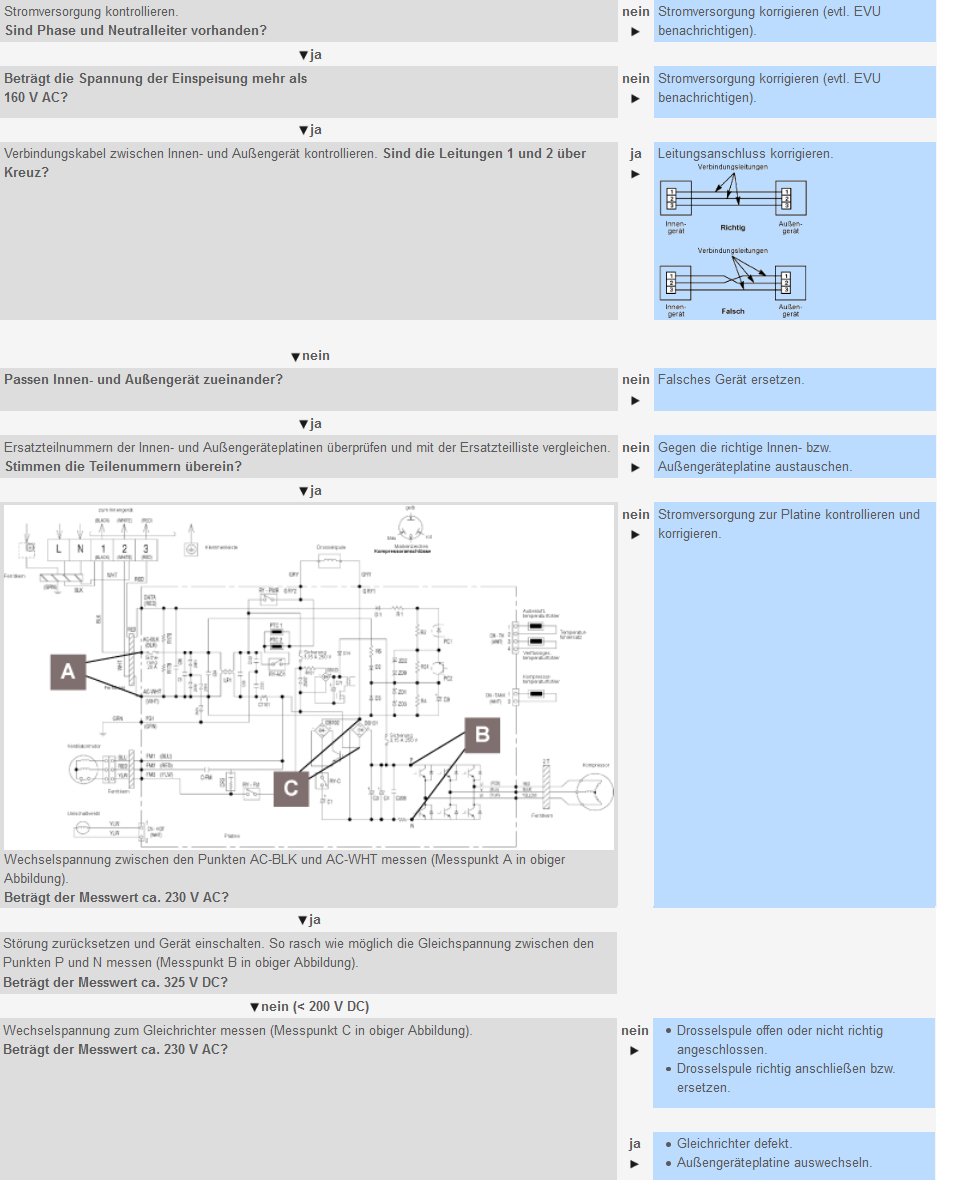

Fault codes of the multi-split inverter systems using the LEDs on the circuit board of the outdoor units CU-3E23CBPG and CU-4E27CBPG

LED:

Note:

Turn the power off, then on. If the green LED A lights up permanently, the outdoor unit circuit board is defective.

For safety reasons and to prevent damage to components, always disconnect the power supply before disconnecting and reconnecting a component.

H00 No fault

H11: Communication fault between indoor and outdoor units

Precondition: >1 min after commissioning

Emergency mode: Only recirculated air

to be checked:

- Cable connections internal and external as well as circuit boards on indoor/outdoor units

Possible causes:

- Faulty expansion valve.

- Faulty line temperature sensor.

- Faulty outdoor unit circuit board

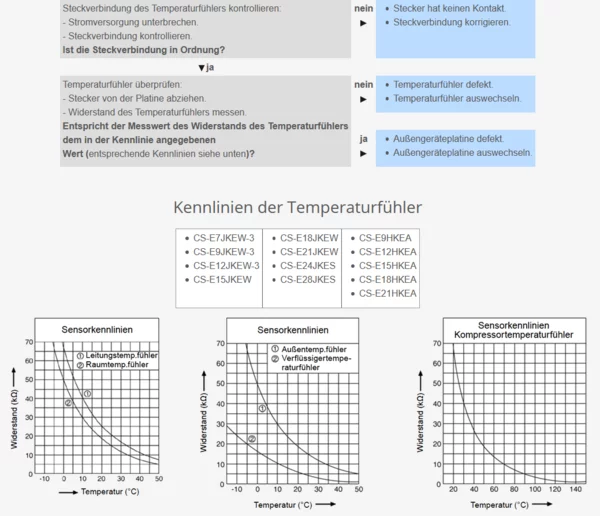

Check and rectify see figure.

H12: Unsuitable performances of indoor and outdoor units

Priority check: Occurs only with multi systems

Possible causes:

- Incorrect models connected to each other.

- Wrong indoor and/or outdoor unit circuit boards used

- Indoor or outdoor unit circuits board defective.

- Incorrect wiring between indoor and outdoor unit.

- Data transmission line No. 3 between indoor and outdoor unit interrupted.

For checking and rectification see figure.

H14: Indoor unit intake temperature sensor

Requirement: 5 seconds long

Priority check: Room temperature sensor (defective or not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

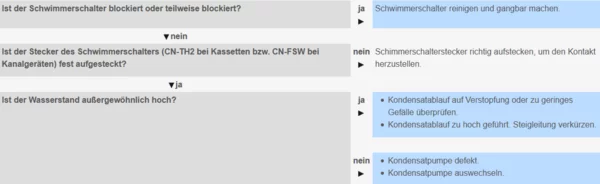

To check and rectify see figure.

H15: Compressor temperature fault

Requirement: 5 seconds long

Priority check: Room temperature sensor (defective or not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H16: Transformer in outdoor unit is open

Priority check: Circuit board in the outdoor unit power transistor module (IPM) compressor defective (compressor too low)

Possible causes:

- Refrigerant deficiency.

- Transformer defective.

- Outdoor unit circuit board defective.

- Compressor defective (low compression).

For checking and rectification see picture.

H19: Indoor unit ventilator module blocked

Preconditions: 7 times in series

Priority check:

- Circuit board in the outdoor unit

- Power transistor module

- Compressor defective

Possible causes:

- Faulty motor connection on the circuit board.

- Defective fan motor.

- Faulty indoor unit circuit board.

- Fan motor mechanically blocked.

For checking and rectification see figure.

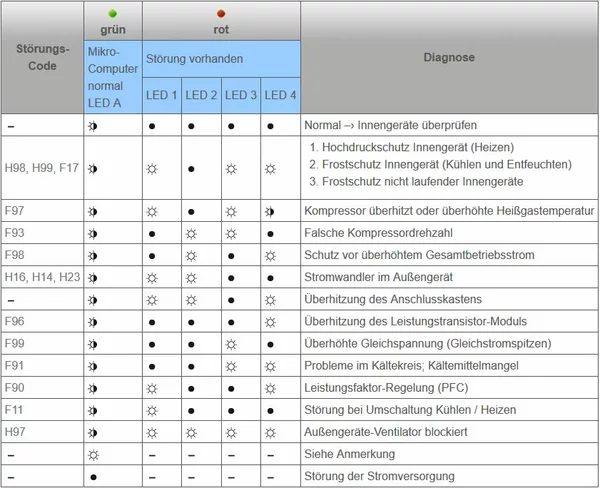

H21: Float switch in the indoor unit

Priority check: Float switch

Possible causes:

- Condensate pump clogged or no slope

- Faulty condensate pump (CN-DRMTR).

- Float switch not connected (CN-TH2, connections 1 and 2 for cassettes and CN-FSW, Connections 1 and 3 for duct units).

- Float switch defective (blocked in the open position).

- Faulty indoor unit ciruit board.

- Fan motor mechanically blocked.

To check and remedy see figure.

H23: Indoor unit heat exchanger sensor

Preconditions: 5 seconds long

Emergency mode: Operation with fixed compressor operating frequency and fixed fan speed (only cooling)

Priority check: Heat exchanger temperature sensor (defective not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H24 Indoor unit heat exchanger sensor 2

Requirement: 5 seconds long

Priority check: Heat exchanger temperature sensor (defective not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H25 E-ion power module malfunction

Priority check:

- Circuit board indoor unit

- e-ion power module

Possible causes:

- Faulty e-ion module (high-voltage generator for positive charging of the filters).

- Faulty circuit board.

- Faulty connection or wiring (open or short-circuited).

For checking and rectification see figure.

H26 Air ioniser fault

Priority check:

- Indoor unit circuit board

- Ioniser

Possible causes:

- Faulty air ioniser circuit.

- Faulty plug connection.

- Faulty circuit board.

To check and rectify see picture.

H27 Outside air temperature sensor

Precondition: 5 seconds long

Emergency mode: Operation with fixed compressor operating frequency and fixed fan speed (only cooling)

Priority check: Outside air temperature sensor (defective not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H28 Outdoor unit heat exchanger sensor

Precondition: 5 seconds long

Emergency mode: Operation with fixed compressor operating frequency and fixed fan speed (only cooling)

Priority check: Outdoor unit heat exchanger temperature sensor (defective not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H30: Hot gas temperature sensor

Precondition: 5 seconds long

Priority check: Hot gas temperature sensor

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H32 Hot gas temperature sensor 2

Requirement: 5 seconds, only for multi-split inverter systems

Priority check: Hot gas temperature sensor 2

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H33 Indoor unit/Outdoor unit connected incorrectly

Priority check: Power supply indoor unit/outdoor unit

Possible causes:

- Wrong power supply (<160 V AC).

- Incorrect indoor or outdoor unit circuit boards

- (EEPROM empty or corrupt).

To check and remedy see picture.

H34 Heat sink temperature sensor in the outdoor unit

Preconditions: 2 seconds, only for multi-split inverter systems

Priority check: Heat sink temperature sensor in the outdoor unit (defective or not connected)

Possible causes:

- Faulty connection.

- Sensor fault.

- Faulty circuit board.

To check and rectify see figure.

H35 Condensate pump

Priority check: Condensate pump, condensate line

Possible causes:

- Float switch blocked.

- Connection plug of the float switch.

- Fall of the condensate drain or riser too high.

- Faulty condensate pump.

To check and rectify see figure.

H36 Suction gas temperature sensor in the outdoor unit

Preconditions: 2 seconds, only for multi-split inverter systems

Priority check: Suction gas temperature sensor in the outdoor unit (defective or not connected)

To check and rectify see figure.

H37 Fluid temperature sensor in the outdoor unit

Preconditions: 2 seconds, only for multi-split inverter systems

Priority check: Fluid temperature sensor in the outdoor unit (defective or not connected)

To check and rectify see figure.

H38 Incorrect indoor unit/outdoor unit combination

Priority check: Please contact one of our technicians

H39 Faulty operation of indoor unit

Preconditions: Only for multi-split inverter systems

Priority check:

- Wrong line connections

- Wrong wiring between indoor and outdoor unit

To check and rectify see figure.

H41 Incorrect wiring or piping (only CU-2E)

Preconditions: Only CU-2E15

Wiring or piping between indoor and outdoor unit incorrect.

- At outside temperatures above 5°C, the line temperature of an indoor unit that is not supplied by the outdoor unit drops by over 20 K to 5°C or less 3 minutes after the compressor starts.

- The suction gas temperature of an indoor unit that is not supplied with power by the outdoor unit drops by over 5 K to 5°C or less 3 minutes after the compressor starts.

Priority check:

- Assembly error: Lines to the indoor units interchanged

Detection of the fault

- When starting up after switching on the power supply 3 minutes after starting the forced cooling mode.

H50: Indoor unit ventilation fan motor

Preconditions:

- AC-Robot only (CS-XE9 / 12EKE)

- 7 times in a row

Priority check:

- Circuit board indoor unit

- Ventilation fan motor

- Ventilation hose

To check and rectify see figure.

H51 Filter cleaner blocked

Preconditions: 2 times in a row Only AC-Robot CS-XE9 / 12EKE

Priority check: Filter cleaner (suction nozzle)

To check and rectify see figure.

H52 Malfunction of the filter cleaning system limit switches

Preconditions AC-Robot only (CS-XE9 / 12EKE)

Priority check:

- Limit switch

- Indoor unit circuit board

To check and remedy see picture

H58 Gas sensor malfunction

Preconditions: Unsuitable output signal from the gas sensor (5 V DC or 0 V DC).

Priority check:

- Faulty gas sensor

- Faulty connection

- Faulty circuit board

Detection of the fault

- The gas sensor emits a signal Vg of 5 or 0 V for 6 hours.

For checking and rectificationsee picture.

H97 Outdoor unit fan motor blocked

Preconditions:

- Loss of the fan motor synchronization signal.

- A speed greater than 2550 min-1 or less than 50 min-1 is determined.

Priority check:

- Faulty fan motor.

- Faulty outdoor unit circuit board

Detection of the fault

- If it is determined 3 times within 60 minutes or 2 times within 30 minutes that the motor speed and

- control signal were out of synchronisation 5 times in succession, this error message appears, and the device is switched off.

To check and rectify see figure.

H98 High pressure protection indoor unit

Preconditions: In heating mode, the heat exchanger temperature of the indoor unit is more than 60°C.

Please note: The fault code is not displayed (TIMER LED does not flash), but it is saved in the EEPROM.

Priority check:

- Dirty air filter in the indoor unit.

- Dust build-up on the evaporator.

- Air-side short circuit.

- Incorrect measured value of the line temperature sensor.

- Incorrect measured value due to faulty indoor unit circuit board.

- Outside temperature too high.

- Outdoor unit fan.

- Excess refrigerant.

Detection of the fault

In the heating mode, the line temperature of the indoor unit is more than 60°C.

To check and rectify see figure.

H99 Frost protection indoor unit

Preconditions: Frost protection is activated if the line temperature of the indoor unit is below a certain value for too long (HKEW: 2°C).

Possible causes:

- Dirty air filter in the indoor unit.

- Dust deposit on the evaporator.

- Short circuit on the air side.

- Incorrect measured value of the line temperature sensor.

- Incorrect measured value due to faulty indoor unit circuit board.

For checking and rectification see picture.