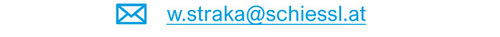

Multi compressor refrigeration packs & special systems

As Europe's leading wholesaler in the field of refrigeration and air conditioning technology, we offer you a wide range of compound and special systems as well as waterloop systems and control cabinets. For customised projects, we advise you from planning to production. We are your competent partner for systems with natural refrigerants such as CO2, propane and ammonia as well as chemical refrigerants of classes A1 and A2L. Our team of experts has many years of experience and emphasises the highest quality, reliable and future-oriented technology as well as service friendliness.

High-quality multi compressor packs

We attach particular importance to reliability, which is why we only use components that meet our high quality standards.

Our refrigeration systems feature high-quality components from renowned manufacturers and flawless workmanship. They therefore enjoy a high level of acceptance.

Based on the requirements of the market and the individual needs of our customers, we work together to develop sustainable and future-proof solutions.

We use fully and semi-hermetic compressors from all well-known manufacturers as well as screw compressors for larger systems.

We design all systems using the latest 3D technology and manufacture the cable segments in our innovative bending center. You can choose from many options for your system.

Applications

Our products are used in a wide range of applications, such as:

- Interconnected systems for trade and gastronomy

- Interconnected systems for supermarket

- refrigeration Large refrigeration systems for industrial refrigeration Food production

- Liquid cooler for cold water and cold brine production

- Refrigeration and air conditioning systems for marine applications

- Special systems for process engineering or test benches

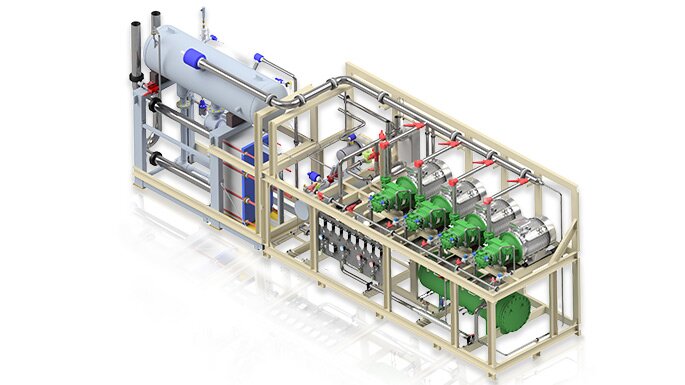

Our catalogs: The most important information at a glance

- Clear tables for a quick comparison of technical data and performance

- Information on legal regulations Installation instructions

Realized projects (selection)

Our systems are used worldwide and are individually tailored to the needs of our customers.

-

Intermarche France: Supermarket, 8 units

Spar France: Supermarket, 22 Units

Auchan France: supermarket, 59 units, Assembly: Engie Axima, Kühlmöbel Epta

Auchan Spanien: 21 Einheiten, refrigeration furniture: Koxka

-

Walmart Mexico: 4 supermarkets, 200 units, Assembly: Hussman

Stokrotka Poland: 38 supermarkets, 200 units

Take a look at Schiessl's own production facility: 450 kW multi compressor pack for cooling, heating and heat recovery

Questions and answers on multi compressor refrigeration systems

What is a multi compressor refrigeration system?

A multi compressor refrigeration system is a combination of two or more compressors that is used in refrigeration technology. These systems are particularly useful when multiple refrigeration points are required, such as in supermarkets, central warehouses, logistics centers or butcher's shops. Depending on the requirements, reciprocating compressors, screw compressors or scroll compressors are used. These compressors provide the optimum solution for individual requirements.

What are the advantages of multi compressor refrigeration systems?

Energy efficiency: Interconnecting several machines saves costs and energy. Interconnected systems can be optimally adjusted to different cooling capacities. They are specially developed to be energy optimized and aim for the lowest possible power consumption.

Flexibility: They offer high flexibility in design and compact construction as well as simple expansion options.

Heat recovery: Heat is generated during the production of refrigeration, which can be reused through heat recovery.

Simple expansion: The smart networking allows the easy addition of further refrigeration systems or cooling points. In the event of a compressor failure, operation of the other compressors is maintained without further ado.

Sustainability: Environmentally friendly refrigerants such as CO2 and propane as well as resource-saving materials are an important aspect in the construction of compound systems.

Robust design: A reliable interconnected system should continue to function even if individual components malfunction or fail. Redundancy and power reserves are important here.

How does a multi compressor refrigeration system work?

A refrigeration system is controlled by electronics. This controls an evaporator, which controls the temperature of the refrigeration points. In order to achieve the desired value, suction pressure is generated, the gas is compressed and the desired cooling is generated in the condensers. Different suction pressures can be achieved with a combined system, which is an advantage when supplying different areas with different temperatures.

What types of multi compressor refrigeration system are there?

Parallel system: This type of system consists of several compressors that work in parallel in a refrigeration circuit and supply one or more evaporators. They are particularly common in facilities with highly fluctuating refrigeration requirements, such as supermarkets or room air conditioning systems. The capacity is adjusted by switching off compressors or controlling the speed.

Interconnected refrigeration systems: These systems are used to cover large capacity ranges. They consist of compressors connected in parallel, often with speed-controlled compressors. Supermarkets, hospitals and hotels often use compound refrigeration systems.

Composite compressor sets: These are normally supplied as complete compressor sets and connected to the rest of the refrigeration or air conditioning system on site. They offer a good adjustment of the cooling capacity to the system requirements.

The choice of a suitable compound system depends on the specific requirements and the area of application. Each type has its own advantages and disadvantages, but overall, multi compressor refrigeration system enable efficient and reliable refrigeration and air conditioning solutions.

Where are multi compressor refrigeration systems used?

Supermarkets: Interconnected systems are often used in supermarkets as they can efficiently cover the highly variable refrigeration requirements.

Central warehouses and logistics centers: Large warehouses with a high turnover of goods benefit from compound refrigeration systems.

Hospitals: Multi compressor refrigeration systems are ideal for supplying different areas with different temperatures.

Hotels: Hotels use compound refrigeration systems to efficiently cover their cooling needs.

Catering and food industry: In these sectors, multi compressor refrigeration systems are widely used to supply refrigeration points.