- Produkte

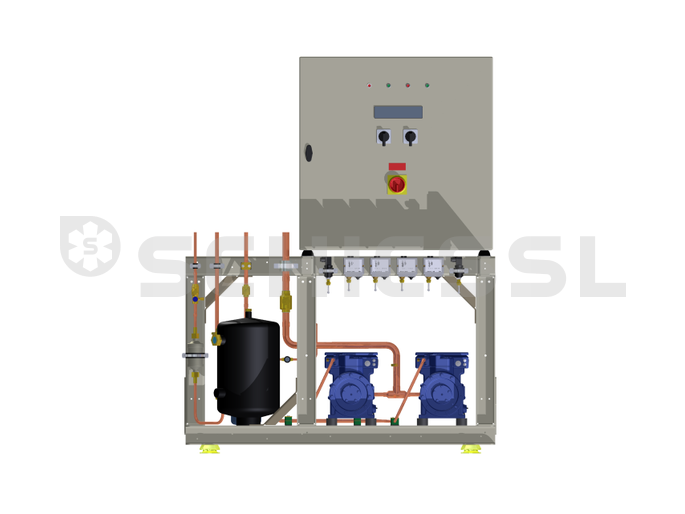

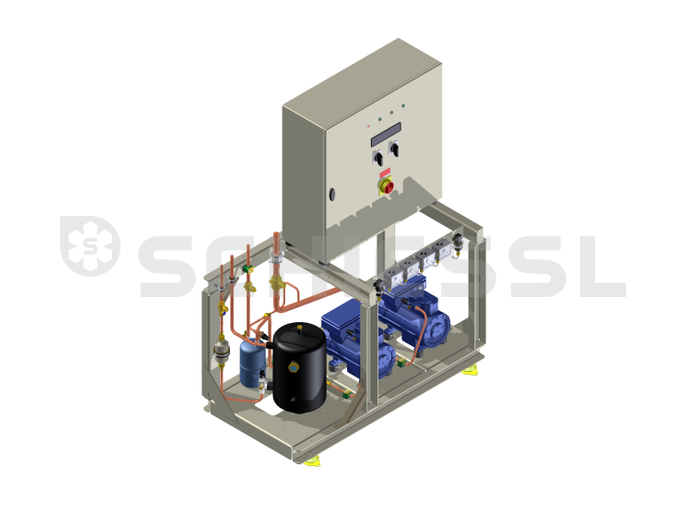

- Euro Line compressor unit *FU* regulated E-FU-2BO-1 V3 HGX12P/110+CIMR-AC4009FAA

Euro Line compressor unit *FU* regulated E-FU-2BO-1 V3 HGX12P/110+CIMR-AC4009FAA

One click to the most important information:

Description

Frequency-controlled Bock power racks operate using two semi-hermetic HI series compressors, where one frequency-controlled compressor takes the role of the master compressor and the second compressor is activated unregulated by the frequency converter. These units have been specially ...

Frequency-controlled Bock power racks operate using two semi-hermetic HI series compressors, where one frequency-controlled compressor takes the role of the master compressor and the second compressor is activated unregulated by the frequency converter. These units have been specially developed for use in refrigeration systems with variable refrigeration demand. The use of a Power Electronics Yaskawa frequency converter allows compressors to run continuously while optimally adjusting cooling performance to the current conditions.

The partial load behaviour has been further optimised compared to the E-FU-1BO devices by dividing power across two compressors. These devices are therefore an energy-efficient and space-saving alternative to power racks with multiple compressors. The Bock power racks are available in 6 different performance classes. Refrigerants R134a/R404A/R507/R513A/R450A/R448A/R449A can be used. The maximum frequency may be limited for air conditioning applications. Cooling power is regulated depending on the intake pressure.

A Power Electronics Yaskawa frequency converter is used in combination with a pressure transmitter to control the power rack. This is mounted and thermally decoupled on the intake side and records the actual intake pressure value. The frequency inverter regulates the cooling power of the rack so that the target value is achieved as closely as possible. The frequency converter is included with the control box. Configuration is input via a keyboard. The frequency convertor comes pre-configured. Only a small number of parameters must be changed to make changes to the refrigerant used and the place of use. The control box is mounted to the frame and wired. All components are mounted to a tough riveted steel profile frame. All parts of the frame are powder-coated. The power rack stands on the supplied rubber-bonded metal base. Refrigeration lines are conveniently grouped together at the rear and can be shut off. Power racks are fitted with an oil separator as standard in order to ensure reliable operation, even during a temporary minimal cooling load on the system.

Features

- optimally adapt compressor performance to changing loads on the refrigeration system

- very low minimum cooling power

- optimal temperature and quality for refrigerated goods

- minimal space needed due to compact design

- energy saving from better performance control in optimal evaporating ...

- optimally adapt compressor performance to changing loads on the refrigeration system

- very low minimum cooling power

- optimal temperature and quality for refrigerated goods

- minimal space needed due to compact design

- energy saving from better performance control in optimal evaporating temperatures

- standard components mean it is easy to service

- reduce the installed cooling power and thus the cost of investment by use of coincidence factor

- simple installation of a heat recovery systems using a common heat exchanger for all areas to be cooled

Scope of delivery

- Control box with Power Electronics Yaskawa frequency converter, installation and wired

- semi-hermetic compressor from GEA Bock with crankcase heater

- compressor shut-off valves

- fluid collector

- refrigerant dryer / inspection glass

- filling valve in the fluid line

- ball shut-off valve in the pressure, ...

- Control box with Power Electronics Yaskawa frequency converter, installation and wired

- semi-hermetic compressor from GEA Bock with crankcase heater

- compressor shut-off valves

- fluid collector

- refrigerant dryer / inspection glass

- filling valve in the fluid line

- ball shut-off valve in the pressure, fluid and suction lines

- pressure transmitter, suction pressure -0.5 - 7 bar

- pressure transmitter, high pressure 0 - 30 bar

- high pressure monitor, type tested for each compressor

- combined high/low pressure monitor, type tested

- low pressure monitor, type tested for emergency operation

- oil separator with inspection glass and shut-off valve in the return line, with electrical heating

Accessories / Replacement parts

-

Filter insert

-

Frequency convertor

-

Intake pipe filter